Failure Patterns

Introduction:

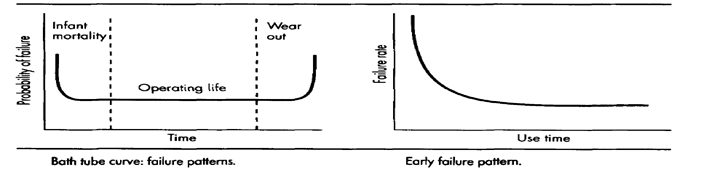

It is generally believed that there are three main patterns of equipment component failure.

Failure patterns:

1 Infant mortality zone:This is an area where faults can result from poor design, assembly or testing of the equipment purchased. This type of failure can be dealt with by processes of good supplier management (quality at source) or burning-in period and by allowing equipment to be operational for a predetermined period of time before shipment to the customer concerned.

2 Random failures:This is the period of normal working life of the equipment and where performance can be expected to be at an optimum. The chances of failure are expected to be low in this period and failures which take place tend to happen randomly and are therefore unpredictable.

3 Wear out zone:This is the phase where wear and tear can lead to a high rise in the number and frequency of disruptions of the equipment. The probability of failure rises sharply and important decisions have to be made at that stage about the future of the process equipment in question.

Bath tub curve:

The bath tub curve is widely used as the standard reliability failure plot. However, it is thought that most processes do not exhibit behaviour such as the one depicted.

- Only 4% of equipment/components exhibit behaviour based on the bath-tube curve (infant mortality - stable period - wear out period);

- 68% of equipment follows behaviour of failure which occurs at the start of utilisation. Good supplier quality assurance and burning-in periods can usually solve this pattern of failure.

- 14% of the equipment components follow a flat failure pattern, 5. These failures are only subject to routine maintenance such as normal inspection, lubrication, etc.

Minimization of the probability of the failure:

1. Supplier appraisal and equipment selection: This phase is vital if infant mortality failures are to be eliminated. Suppliers have to be selected for their equipment safety, reliability, quality standards, the level of back up and support on offer, etc.

2. A comprehensive TPM programme which will help achieve existing and future customer requirements, through the implementation of efficient routine and long term preventative programmes and through speedy reactions to minimise the level of disruptions when unpredictable failures take place.

3. Apply the principle of derating. Equipment should be treated with care. Longevity will be determined by the type of speeds, settings and operating conditions utilized throughout the life of the equipment.

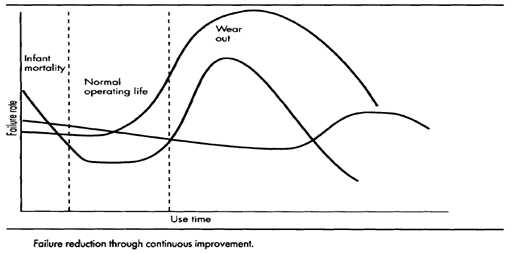

4. The principle of continuous improvement can easily be applied to maintenance.