Joseph M Juran

Introduction:

Juran has contributed as much to total quality as Deming. He was awarded over thirty medals, fellowships, and honorary memberships in some twelve countries. Quality, according to Juran, has to be controlled at each stage of the process but should not be implemented just as a mechanical process.

Juran’s quality approach:

Juran’s approach to Quality Control and its management is two-sided:

(i) Companies’ mission in terms of fitness for use by providing products and services which conform to customer specifications, plus issues of reliability, availability, maintainability, customer service, etc.

(ii) The role of senior managers in providing leadership, in providing the required resources, in encouraging awareness and participation and in developing systems of policy, goals, plans, measures and controls for quality.

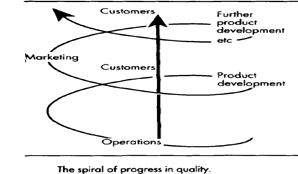

The spiral of progress in quality:

Fitness for use is achieved by a process which reflects the interplay between the various stages or organisational activities before meeting customer demands. The spiral of progress reflects the chain of user-supplier relationships at various stages of the process. Quality, according to Juran, has to be controlled at each stage of the process but should not be implemented just as a mechanical process. It should be aimed at controlling:

- Sporadic problems or avoidable costs (defects and product failure, scrapped materials, labour wasted usage for re-work, repair, dealing with customer complaints);

- Unavoidable costs dealing with chronic problems (prevention and control).

Juran’s quality trilogy:

1. Quality planning

Identify the customers

Determine the customers’ needs

Develop product features

Establish quality goals

Develop a process

Prove process capability

2. Quality control

Choose control subjects (what to control)

Choose units of measurement

Establish measurement

Establish standards of performance

Measure actual performance

Interpret the difference (actual versus standard)

Take action on the difference

3. Quality improvement

Prove the need for improvement

Identify specific projects for improvement

Organise to guide the projects

Organise for diagnosis - for discovery of causes

Diagnose to find the causes

Provide remedies

Prove that the remedies are effective under operating conditions

Provide for control to hold gains